Our team offers specialized solutions for a wide range of industries. Discover some of the most important ones.

Props and fashion

Manufacture of exclusive pieces for product displays

We collaborate with leading brands in the retail and fashion sector in the manufacture of props, supports and technical elements for the display of articles in shops. Our products are present in shop windows and spaces of international brands, where design, finish and visual quality are essential.

Every year we produce more than 200,000 units and develop more than 550 different types, ranging from mannequin stands and articulation components to props for bags, footwear and accessories.

We work in close collaboration with our customers’ technical departments to develop prototypes, optimise processes and ensure a high level of visual and functional manufacturing.

What manufacturing processes do we apply?

- Manufacturing process design and detailed technical documentation

- Tooling manufacture to ensure efficiency and repeatability

- TIG, MIG and laser welding in steel and stainless steel

- Machining on lathe and CNC centres

- High precision 2D and 3D laser cutting

- Sheet metal forming using press brakes and presses

- Mirror polishing, manual or robotic

- Cylindrical and horizontal satin finishings

- High-end finishing: mirror polishing, etching, graphitising, anodising, gold plating, painting

- Final assembly to the highest standards.

Architecture

Engineering and development of customised solutions

We work hand in hand with architectural and engineering firms in the development of customised solutions. These include mobile architectural elements for enclosures, roofs and customised structures, as well as security enclosures.

Thanks to our in-house expertise and capabilities, we handle the entire process, from CAD design and SolidWorks to final assembly and commissioning, including component manufacturing.

What manufacturing processes do we apply?

- CAD design and technical documentation with SolidWorks

- Manufacture of customised metal structures

- Selection and procurement of specific commercial components

- Assembly, electrification and functional testing

- Final assembly ready for on-site installation

Automotive

Engineering solutions for automotive paint lines

We develop customised machinery for painting lines in the automotive sector, working with manufacturers specialising in anti-corrosion processes. . Thanks to our experience in industrial design and technical manufacturing, we participate in all phases of the project: from the initial engineering to the final delivery of the equipment.

We manufacture and integrate essential equipment such as industrial ovens, tippers, elevators, conveyors and coolers, ensuring their correct operation within automated systems.

Our Technical Office collaborates hand in hand with the engineering teams of each client to adjust designs, optimise manufacturing times and guarantee customised solutions for each production line.

What manufacturing processes do we apply?

- CAD design and technical documentation with SolidWorks

- Fabrication of metal structures and components

- Selection and procurement of commercial components

- Programming of PLCs and SCADA systems

- Electromechanical assembly, electrification and functional testing

Construction

Advanced solutions for the construction sector

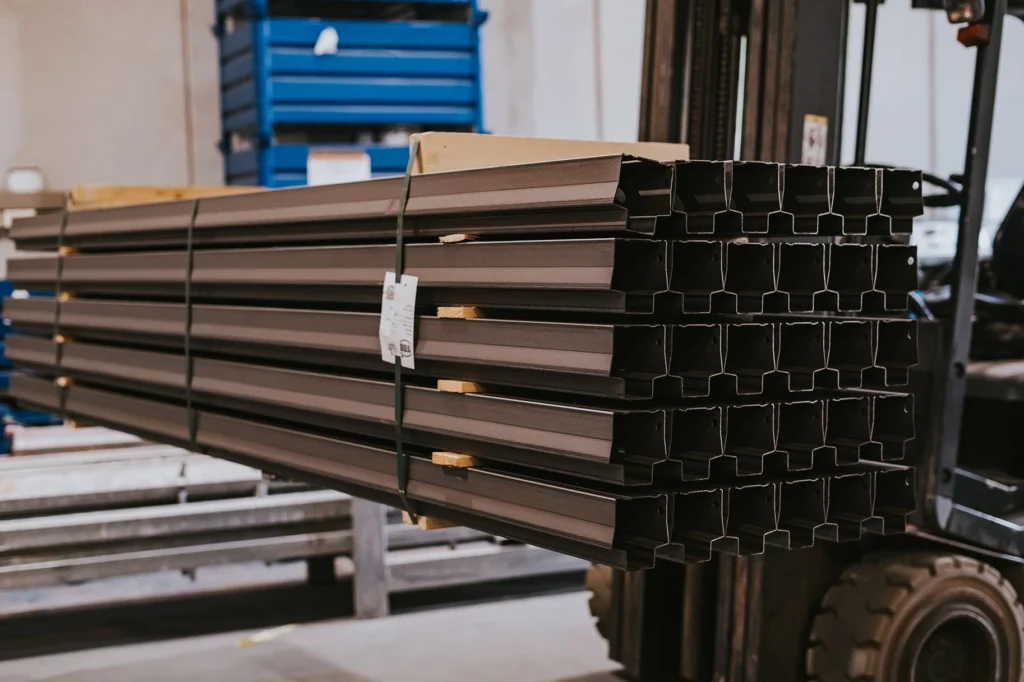

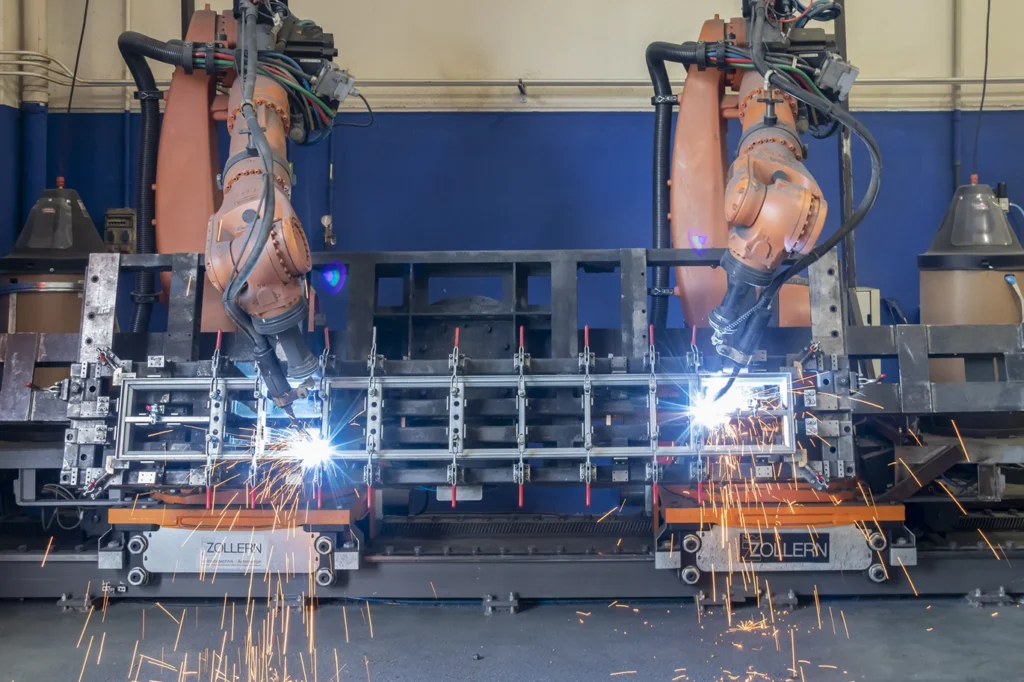

We act as a trusted partner, providing manufacturing capabilities for a wide range of products, such as panels, braces, clamps, props, railings, shoring, purlins and more. These products are mainly made of steel and aluminium, and some of them require large welding cells.

Every year, we manufacture more than 720,000 units of components, producing more than 200 different product typologies, each with its corresponding bill of materials, manufacturing route and detailed technical documentation.

Thanks to close collaboration with our customers’ technical teams, we continuously improve processes, validate prototypes and adapt each product to their technical and logistical requirements.

What manufacturing processes do we apply?

- Manufacturing process design and detailed technical documentation

- Tooling manufacturing to ensure quality and efficiency

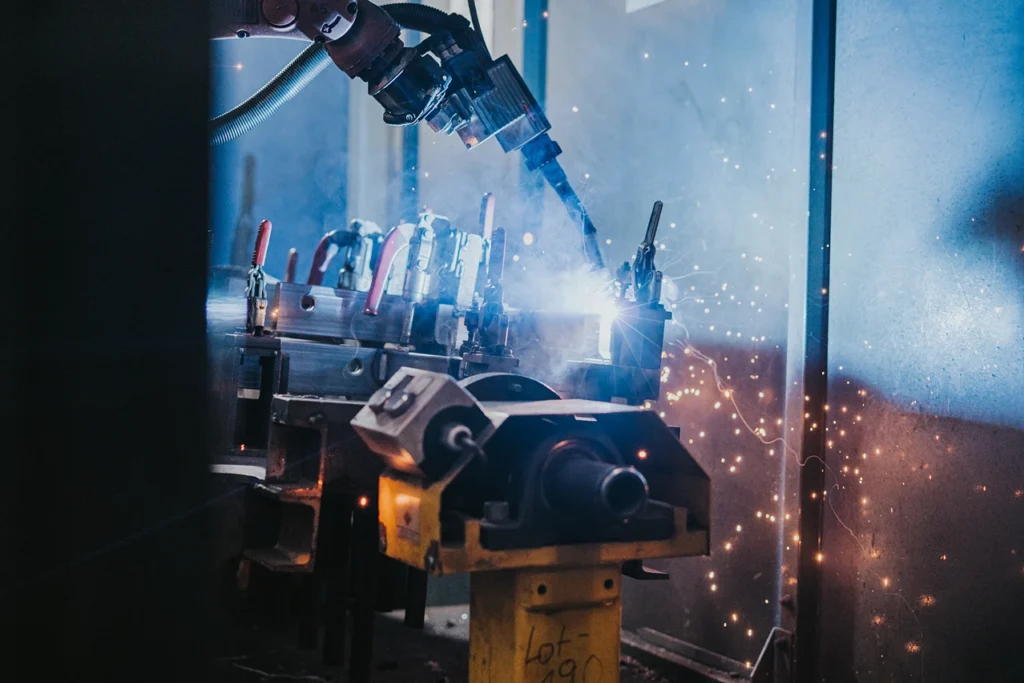

- TIG, MIG and laser welding on steel and aluminium

- Robotised welding cells up to 7 metres in length

- Machining on lathe and CNC centres

- High precision 2D and 3D laser cutting

- Finishing such as zinc plating, hot-dip galvanising and painting

-

Assembly and final assembly with integrated quality control

Horeca

Manufacture of components for the Horeca sector

We work with Horeca sector leaders such as Tubing Food S.A. to manufacture stainless steel columns, dispensers and components for the dispense of beer and beverages.

Our products are essential for brewers as they serve as branding and design elements in bars and restaurants at national and European level. To this end, we produce more than 200,000 units per year, meeting the highest standards in design, finish and customisation for renowned brands.

Thanks to constant contact with the customer, we optimise each product from conception to mass production, ensuring differentiation, quality and efficiency in each part.

What manufacturing processes do we apply?

- TIG, MIG and laser welding on stainless steel

- High precision 2D and 3D laser cutting

- Machining on lathe and CNC centres

- Mirror polishing by robotic cell

- Cylindrical and horizontal satin finishings

- Premium finishes: graphitised, anodised, gold-plated, painted

- Final assembly with integrated quality contro

Agricultural and livestock industry

Innovation in pig farm equipment

We collaborate with leading companies in the farm equipment market, providing design and manufacturing solutions.. As a trusted partner, we have the knowledge and technology necessary to develop innovative products that optimise waste management in the livestock sector.

Working closely with the customer’s technical teams, we refine each product from initial design to final validation, ensuring quality, performance and regulatory compliance.

Among the equipment we have developed, the following stand out:

- Solid-liquid separators for slurry generated on farm.

- Submersible agitators to remove slurry in ponds

This equipment contributes to a more sustainable management, reducing the environmental impact and improving the efficiency of livestock farms.

Working closely with the customer’s technical teams, we refine each product from initial design to final validation, ensuring quality, performance and regulatory compliance.

What manufacturing processes do we apply?

- CAD design with SolidWorks

- Manufacture of prototypes and field tests

- Technical documentation and user manuals

- CE certification

- TIG, MIG and laser welding on steel, stainless steel and aluminium

- Robotic welding cells

- Machining on lathe and CNC centres

- 2D and 3D laser cutting

- Sheet metal forming with presses and press brakes

- Complete assembly and assembly

General Industry

Manufacturing for multiple industrial applications

We collaborate with leading manufacturers in diverse sectors such as lighting for swimming pools, urban equipment, wellness products, electrical resistors, machinery for surface finishes or components for food and energyléctricas, maquinaria para acabados superficiales o componentes para alimentación y energía.

We produce from technical parts to functional assemblies, adapting to every need with customised solutions, complete traceability and high quality standards. Our technical and production capacity allows us to deal with a wide variety of products with efficiency and precision.

We place all our technical and human resources at our customers’ disposal.

What manufacturing processes do we apply?

- CAD design with SolidWorks

- Manufacturing process design and detailed technical documentation

- Development of specific tooling to guarantee precision

- Machining on lathes and high-precision 4- and 5-axis machining centres

- Dimensional verification using metrology equipment

- Tooling manufacturing to ensure quality and efficiency

- TIG, MIG and laser welding on steel, stainless steel and aluminium

- Robotised welding cells up to 7 metres in length

- High precision 2D and 3D laser cutting

- Sheet metal forming with presses and press brakes

- Finishes such as zinc plating, hot-dip galvanizing, painting, technical painting, mirror polishing, satin, anodizing, chrome plating, graphite plating, electropolishing, etc.

-

Assembly and final assembly with integrated quality control

Pharmaceutical and medical

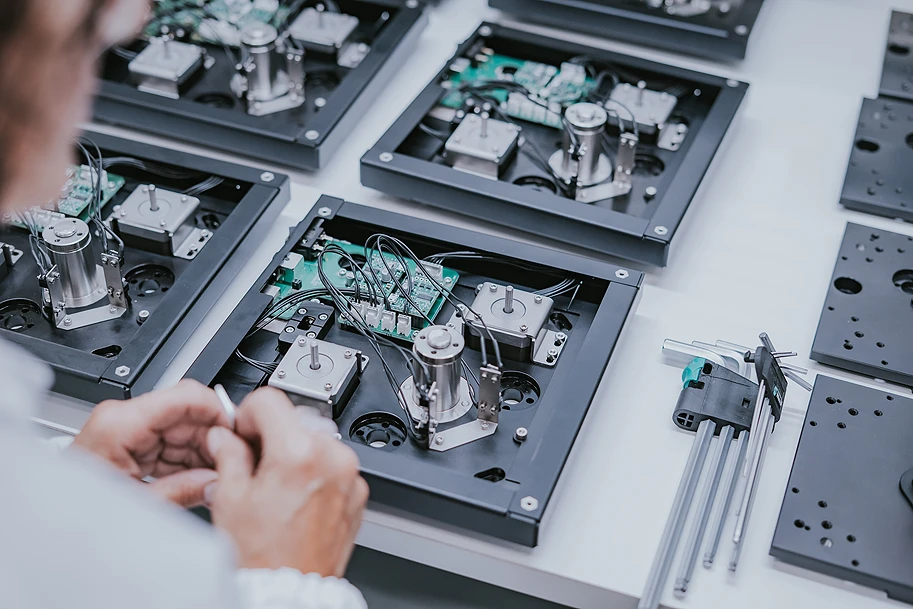

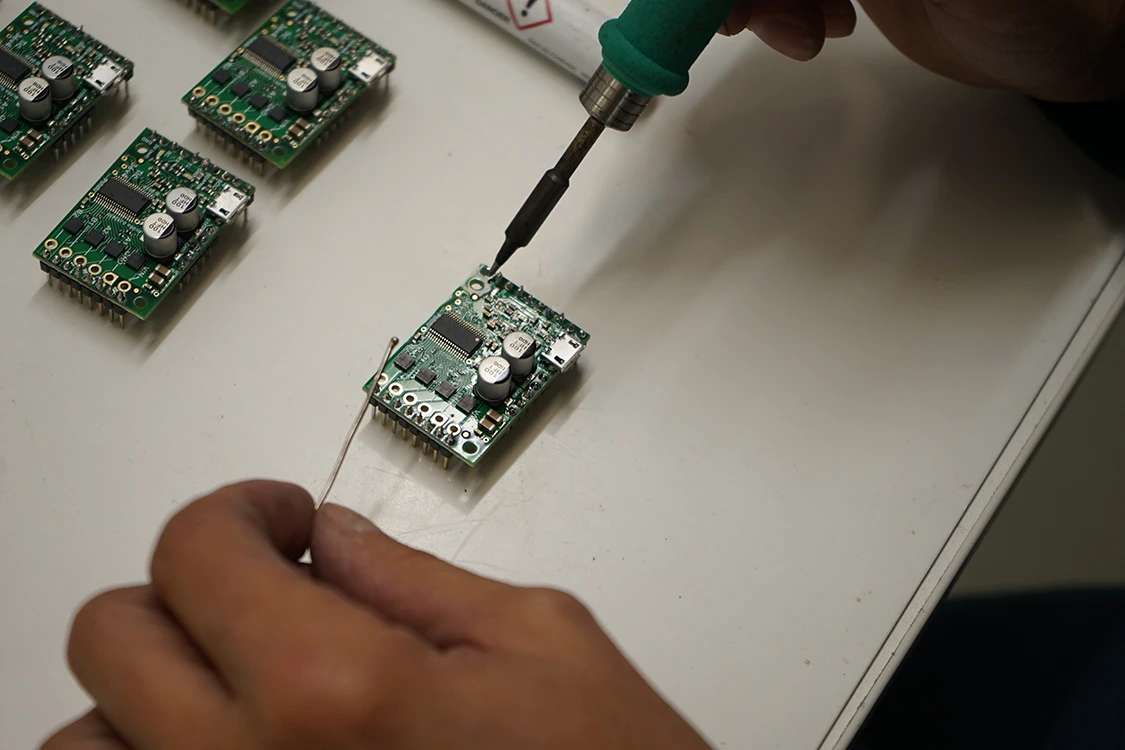

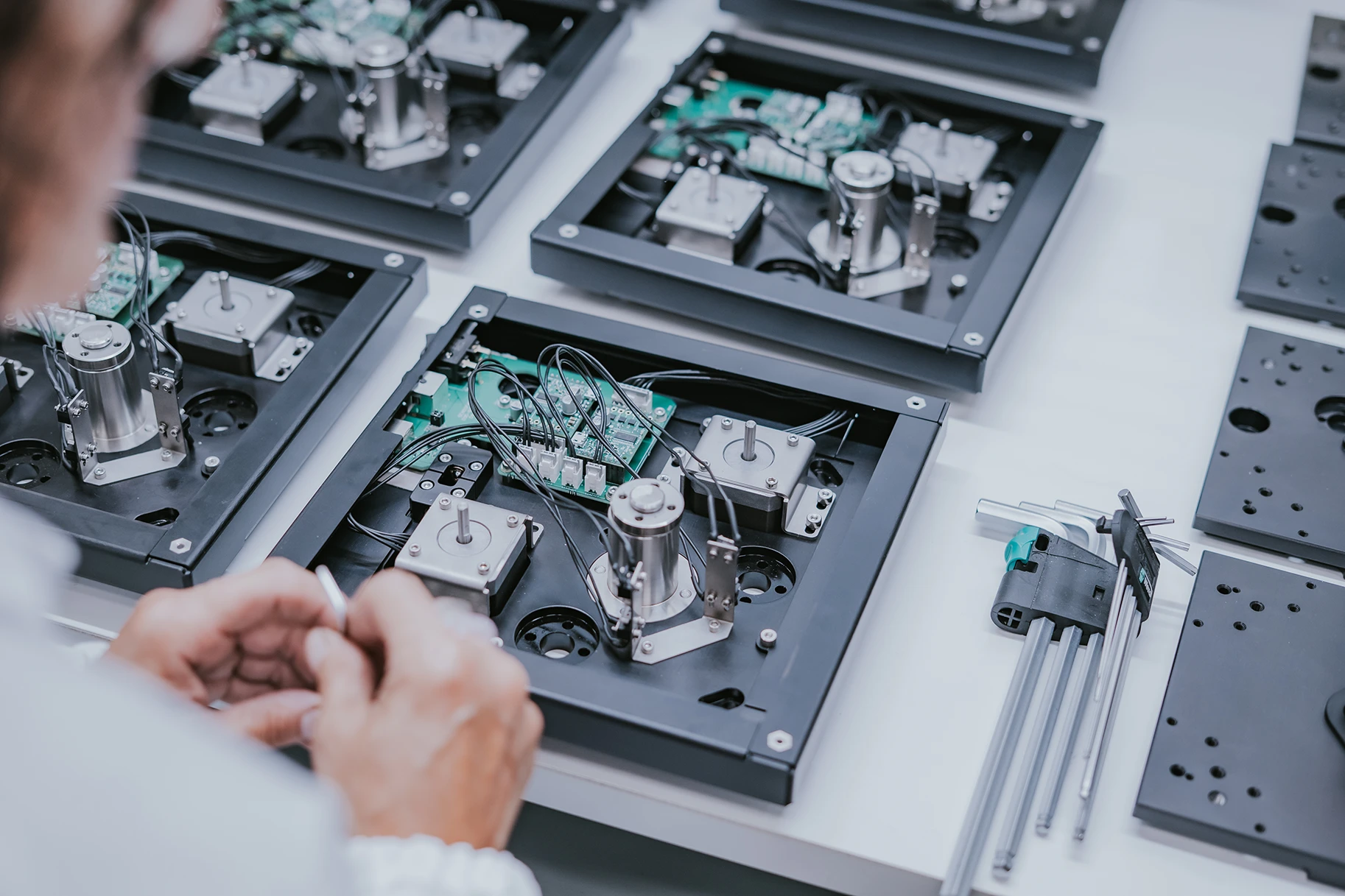

Advanced solutions in optical metrology and precision manufacturing

We are a trusted partner to leading customers in the commercialisation of optical metrology, medical and pharmaceutical equipment.. Our commitment to quality enables us to manufacture components that meet the highest standards in the industry.

We manage complete projects, from technical design and tooling manufacture to final assembly in a semi-blank room, with functional validation and documentary traceability.

We also work closely with our customers’ engineering and R&D departments to develop new products, validate prototypes and apply constant improvements throughout the process.

What manufacturing processes do we apply?

- Manufacturing process design and detailed technical documentation

- Development of specific tooling to guarantee precision

- High-precision machining with 5-axis CNC centres

- Dimensional verification using metrology equipment

- Surface treatments: anodising and technical painting

- Soldering of electronic components

- Assembly of motors, bearings, electronic boards and structures

- Semi-clean room assembly and functional testing

- Technical final packaging for regulated environments