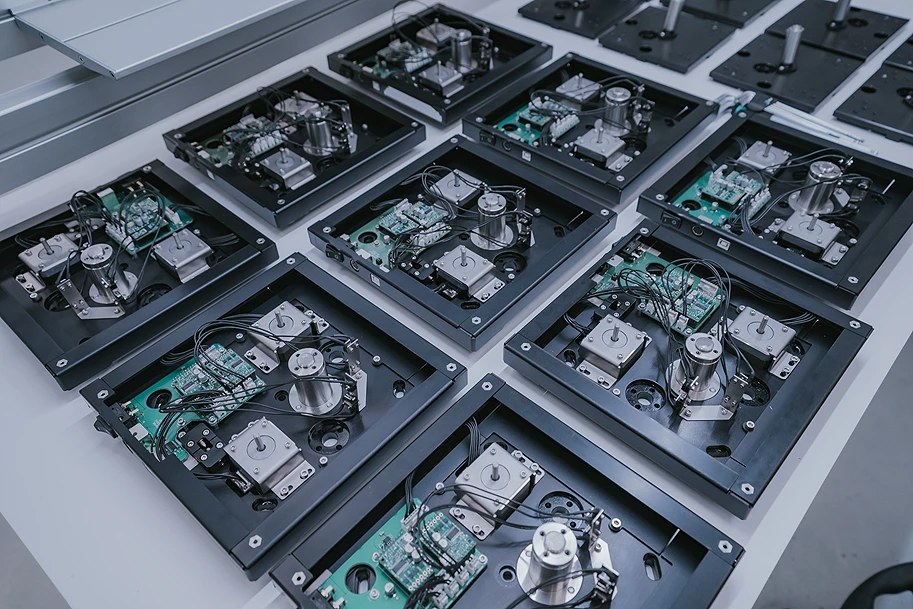

We manufacture made-to-measure metal components and ensure their reliability through advanced dimensional controls. Because in industry, even a micron can make a difference.

Technical machining with industrial vision

We produce technical parts, subcomponents and complex elements for sectors that require minimum tolerances and top quality finishes. We do this by combining experience, agility and a plant equipped with state-of-the-art technology.

What do we do?

Metrology with a guarantee in every micron

Metrology is much more than measuring tolerances: it is ensuring that what we make will work for the customer. Without rigorous verification, even the smallest error can lead to failures in the final product. That’s why at SOLDATAL we combine manufacturing and control in the same workflow.

How do we do it?

- Dimensional verification on the machine itself, Hexagon® and Mitutoyo® three-dimensional equipment.

- Tolerance, roughness and hardness control

- Reverse engineering and optical analysis

- Logging of results for full traceability

All-in-one and integrated

We have a fleet of machinery and technical resources that allows us to control the entire process, guaranteeing deadlines, quality and traceability.